Redefining Factory Floors with Advanced Robotics

Introduction: In the realm of business and industrial operations, the incorporation of advanced robotics has started a new chapter. This technological leap holds the potential to reshape factory floors while providing a competitive edge to forward-thinking businesses.

A Glimpse into the Past and Present of Industrial Robotics

Industrial robots are not a new concept. The first industrial robot, named Unimate, was put to work in a General Motors plant in 1961. Since then, the development and implementation of industrial robots have grown exponentially. Today, these mechanical marvels have become an indispensable part of various industries, including automotive, electronics, and food processing, among others.

The Advent of Advanced Robotics

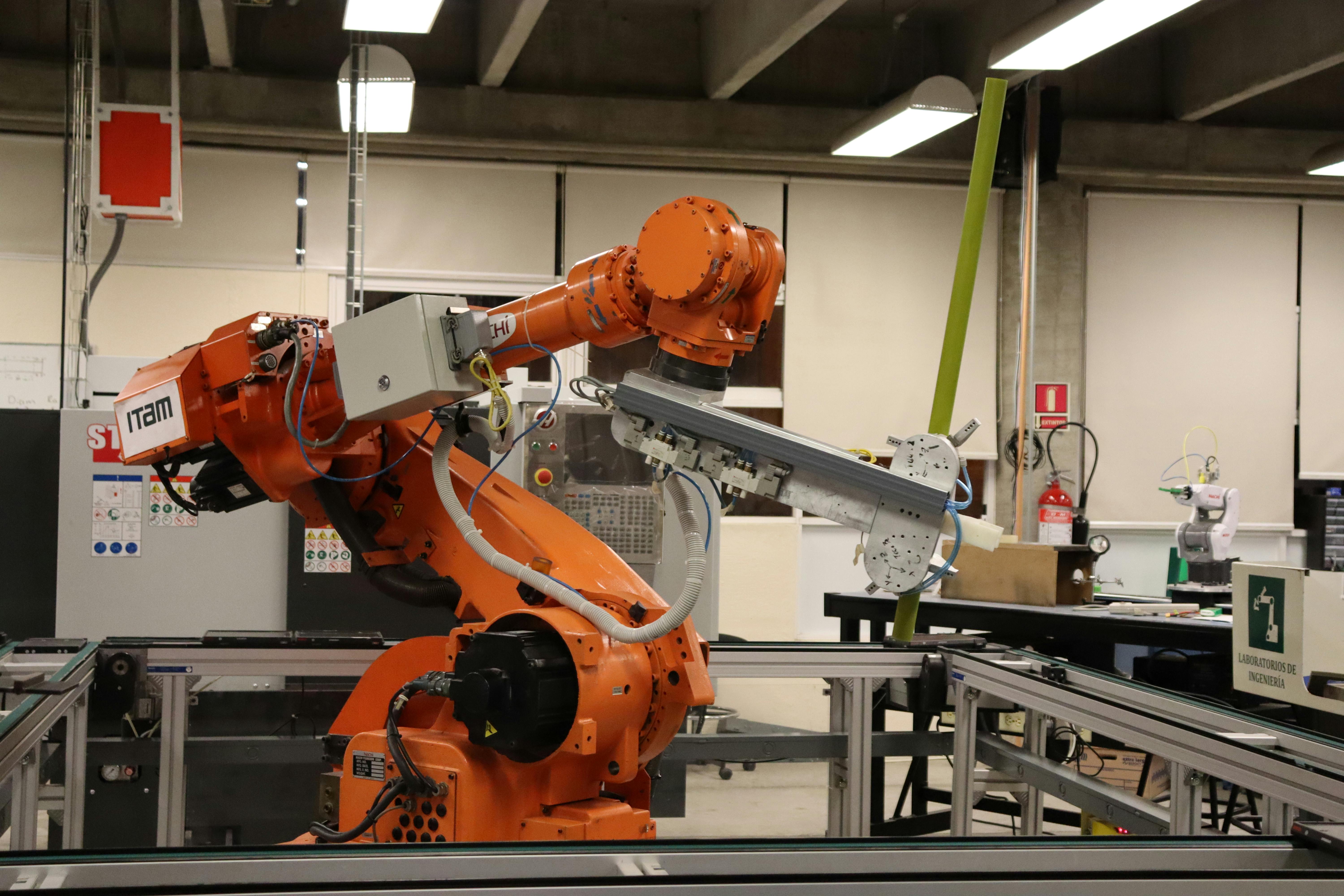

In recent years, the emergence of advanced robotics has started to disrupt traditional industrial practices. Unlike conventional robots that perform repetitive tasks, advanced robots are equipped with sophisticated sensors, powerful processing capabilities, and innovative software. These advancements allow them to learn and adapt on the fly, making them capable of handling complex tasks with greater precision and efficiency.

The Impact on Business and Industrial Operations

The introduction of advanced robotics has far-reaching implications for businesses and industrial operations. On one hand, these high-tech machines can perform tasks faster and more accurately than human workers, leading to significant productivity gains. On the other hand, their ability to learn and adapt means they can take on a broader range of tasks, potentially reducing the need for human intervention in certain areas.

However, implementing advanced robotics is not without challenges. Companies must navigate issues such as high upfront costs, integration difficulties, and workforce displacement.

The Future Prospects of Advanced Robotics

Despite the hurdles, the future of advanced robotics looks promising. As technology continues to evolve, we can expect to see even more sophisticated robots capable of performing increasingly complex tasks. This can lead to further productivity gains, cost savings, and competitive advantages for businesses that embrace this trend.

Practical Applications of Advanced Robotics

- Advanced robots are being used in automotive manufacturing to enhance precision and speed up production.

- In the electronics industry, these machines are helping to assemble intricate devices with unprecedented accuracy.

- Advanced robotics is also finding its way into the food industry, where they are used for tasks like sorting, packaging, and even cooking.

In conclusion, advanced robotics represents a significant leap forward in business and industrial operations. By embracing this trend, businesses stand to gain a competitive edge through increased productivity, cost savings, and the ability to tackle more complex tasks. However, the journey towards this high-tech future requires careful planning, significant investment, and a willingness to navigate the challenges that arise along the way.